When people think of confined space hazards, the mind often jumps straight to air quality or gas leaks. But before a single measurement is taken, there’s a silent risk already present: the configuration of the space itself.

Configuration hazards are hidden in the physical design, layout, and access points of a confined space. The very geometry of the space determines how easily a worker enters, exits, or moves within it. Most importantly, it determines how quickly and safely the worker can get rescued if an accident occurs.

Recognising Configuration Hazards

A confined space may appear harmless from the outside. But inside, you might find:

- Restricted access or egress: narrow hatches, single ladders, or only one way in or out.

- Tight spaces: forcing workers into awkward positions that can cause fatigue or entrapment.

- Complex or curved layouts: such as pipelines or ballast tanks that can disorient workers.

- Slippery or sloping surfaces: increasing fall risks.

When visibility is limited and mobility restricted, even simple tasks can turn dangerous. The more complex the configuration, the higher the risk of delayed rescue and increased exposure time during an incident.

How to Mitigate Configuration Risks

Proper planning and setup can make a major difference.

- Conduct a thorough risk assessment before entry. Identify potential bottlenecks or one-way passages.

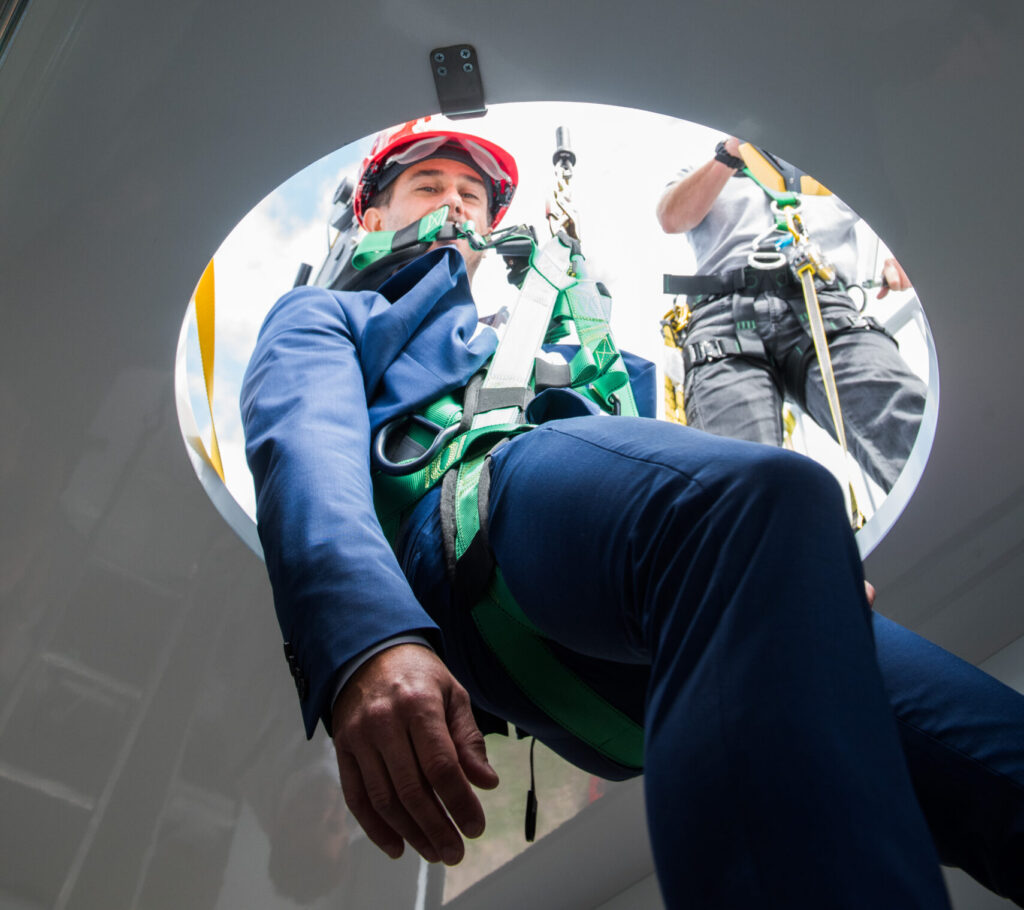

- Use a Confined Space Entry Kit, such as those that include tripods, winches, rescuers and body harnesses, to ensure safe entry and retrieval.

- Establish a standby and rescue plan before work begins — not after something goes wrong.

- Train entry supervisors and attendants to monitor all entrants and maintain constant communication at all times.

At United Resources, we supply a range of Confined Space Entry and Rescue Systems from trusted safety brands like MSA and KStrong, ensuring that teams have the right gear for secure entry, retrieval, and emergency response.

The Bottom Line

Configuration hazards remind us that safety begins before we even step inside. No matter how routine the job, confined space entry demands careful planning and proper equipment. With the right system in place, workers can move confidently knowing that every entry has a safe exit.