It’s that time of year when we tune up, tidy up, and get ready for a fresh start. And when it comes to wire ropes, not all lubrication methods are equal.

Many teams still rely on manual brushing, dripping, or spraying. But like trying to wrap presents with one hand, manual lubrication is not the best way to get good results.

Why Manual Lubing Just Doesn’t Cut It?

- Patchy, inconsistent coverage

Manual brushing coats only the rope’s exterior. This creates dry sections, uneven layers, and leaves internal strands unprotected. It’s like frosting only the outside of a sponge cake and forgetting to fill the centre with jam: it looks pretty, but the fundamentals are missing.

- No pressure means no penetration

Internal wires are where most wear begins. Manual methods can’t push lubricant deep into the rope core, leaving hidden corrosion and friction to build up like a nasty surprise under the tree.

- Messy, wasteful, and costly

Drips, overspray, and flung lubricant turn your worksite into a hazardous and slippery arena. Furthermore, expensive lubricant is wasted in a process that is much better left to machines.

- Slow and unsafe

Standing near moving ropes or shutting down operations to brush lube on manually? That’s more exposure, more downtime, and more manpower than necessary.

Viper’s System: A Gift Your Ropes Deserve

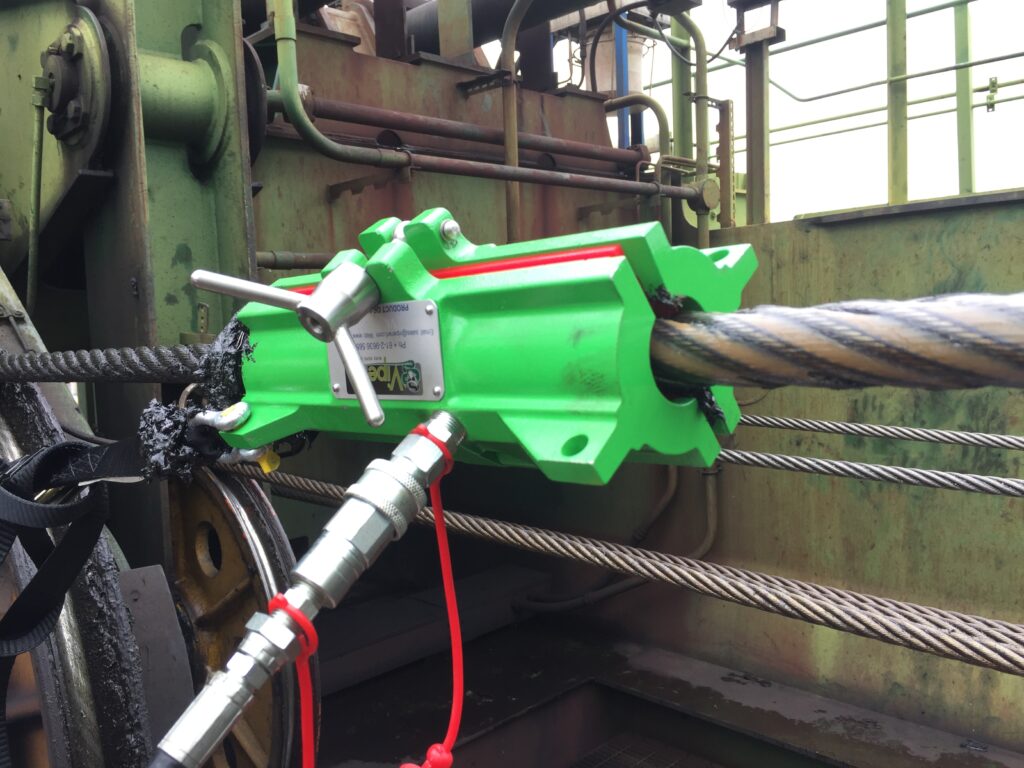

The Viper Wire Rope Lubricator solves every issue that manual lubrication has:

- 360° perfect coverage

A sealed collar ensures full, consistent lubrication around every strand in just one pass. No spots missed!

- Deep pressure penetration

Viper forces lubricant into the rope core at high pressure, protecting internal wires in ways that manual methods can never reach.

- Cleaner, safer, and far less waste

The collar contains the lubricant, reducing splatter and ensuring more of the product ends up in the rope instead of on the floor.

- Faster and with less manpower

Viper’s solution results in in minimal downtime, reduced exposure to danger, and lower labour needs: a real gift to your team.

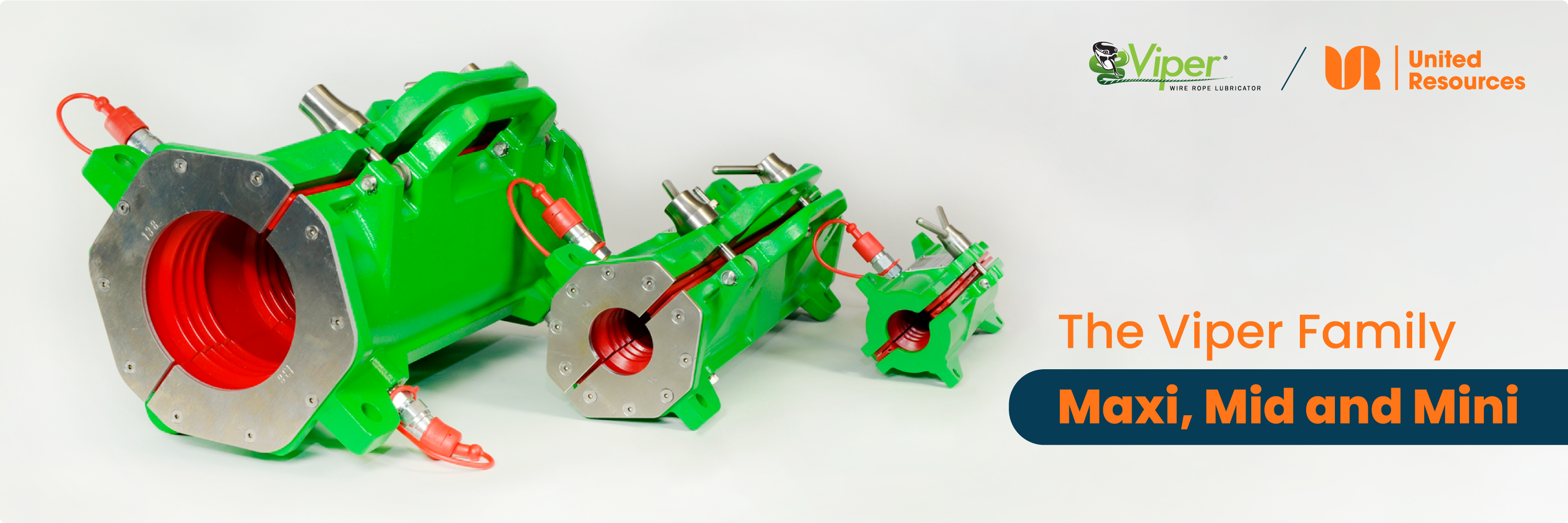

A Viper for Every Season and Every Worksite

Just like how presents come in all shapes and sizes during the holidays, so do ropes. And luckily, Viper Wire Rope Lubricators have a model for almost every one of them. It’s almost like choosing Christmas gifts: there’s a perfect Viper for every rope and work requirement.

Whether your “presents” include:

small-diameter ropes,

large heavy-duty ropes,

long, continuous lengths,

or ropes in harsh offshore or marine environments…

Viper has a solution that applies lubricant evenly, cleanly, and efficiently. Accessories such as groove cleaners are also available, which cleans off residue on pre-seasoned ropes and allows the new lubricant to effectively penetrate their cores.

Manual lubing looks like effort, but it doesn’t deliver true protection. Viper’s wire robe lubricators are consistent and deliver results on every pass, for every strand.

Because ’tis the season to season your ropes… and Viper helps you do it right.

If you would like to explore the right Viper model for your operations, feel free to reach out. Let’s keep your ropes and your workflows running smoothly into the new year and beyond.